In this episode of The WTiN Podcast, we talk to Cam Chidiac, who is the founder of the clean tech firm Drywired.

Drywired is an award-winning, Los Angeles-based business that distributes nanotechnologies globally. The company’s mission is to harness nanotechnology as a catalyst for change with its eco-friendly protective thin-film coatings that can make buildings more energy efficient, surfaces cleaner, lessen e-waste and reduce city air pollution.

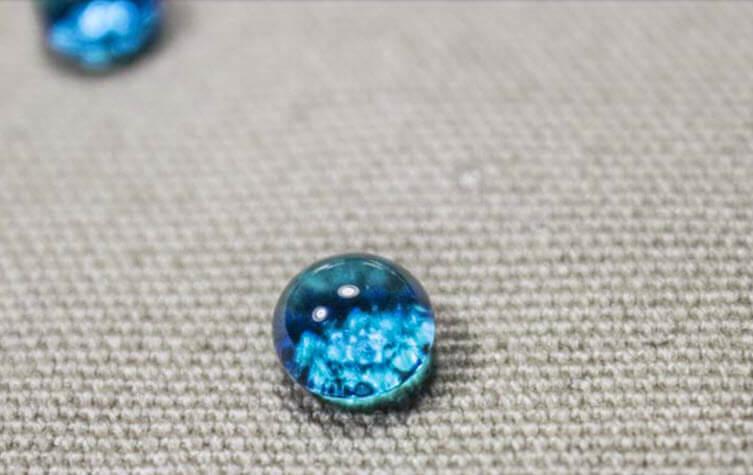

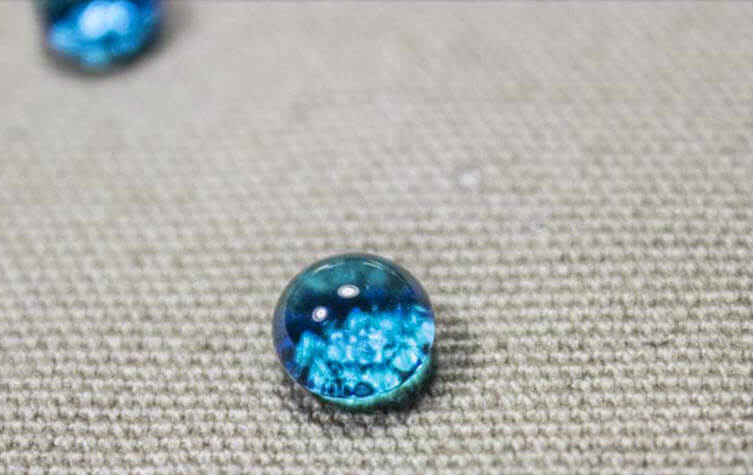

In this podcast, Chidiac starts off by explaining more about how the brand came about. Founded in 2012, it was launched at CES in January 2013 as a start-up offering a single protective nanocoating solution for mobile electronics. The team works by connecting with researchers and scientists to bring research and patents to commercialisation, and its most recent product is called Dryfiber. Dryfiber provides a fluorine-free durable water and oil repellent textile finish, which is completely water-bourne and can be applied through traditional finishing processes.

Chidiac talks about the chemistry involved to achieve oil repellency and he explains more about the issue surrounding toxic chemicals such as PFCs. Elsewhere, he talks about the sea of opportunity for innovation out there. Apparently, 98% of research and patents never reach the market, and so people should really seek these out as a lot of the industry’s problems have already been solved.

Have your say. Join the conversation and follow us on LinkedIn

-

Transcript

This transcription has been AI generated and therefore may have some inaccuracies.

Ep. 28: Drywired develops fluorine free oil repellent finish

In this episode of The WTiN Podcast, we talk to Cam Chidiac, who is the founder of the clean tech firm Drywired.

Jessica Owen

Hello. My name is Jessica Owen, and I'm the Deputy digital editor at WTIN, and this is the WTIN podcast for this series, I'll be talking to startups and other new brands across the textile and apparel industry, from sustainable swimsuits to jackets inspired by NASA technology. We talk about products, the highs and lows of starting a business, and advice for others interested in entering this space. This week, I am joined by Cam Chidiac, who is the founder of the clean tech firm Drywired, Cam talks about the brand's beginnings its latest development called dry fiber, and how 98% of patents and research never reaches commercialisation, right? Well, hello Cam, and welcome to the WTIN podcast. So I understand that you're in LA, so how's everything going over there at the moment? Yeah,Cam Chidiac

Hi. Thanks for having me. So we're in, we're in, stay at home, shut down, still here in Los Angeles, at a minimum for another nine days. And just like the rest of the world, you know, we've had to adapt to the changing rules and spending much more time at home. So we hope in the coming weeks, things will start to normalize again.Jessica Owen

Things crossed so cam, then you founded dry wired back in 2013 I think, and you call yourselves a clean tech firm. So tell me what you mean by this and what you do exactly as a company.Cam Chidiac

Yeah. So when I founded the company in 2013 I was really fascinated with what was happening in ultra thin coatings, so specifically nano technology based coatings, as an outsider with a background in aerospace logistics. You know, I really didn't know a lot about chemistry, and I was kind of self taught, and what I saw was big movement towards multi functional chemistries that were safer for the environment. And so that's one of the reasons we call ourselves a clean tech firm, but also the ability to change structures and the functionality of structures using new methods. And specifically, you know, nanotechnology based research. So, so the excitement around that kind of emerging area prompted me to jump in, found the company, and start to promote some of these new technologies.Jessica Owen

Okay, and so what was the first technology or product that you brought out? So,Cam Chidiac

you know, we like to look at industries that have had very little change for the last 50 years. And the first industry was the aerospace industry and the electronics industry side by side. You know, both were using conformal coatings from the 1960s to provide protection to electronics, so against water damage, oil damage, rust and other kind of exposures and and so these really thick kind of toxic flora, polymer based coatings, again, had had been around for over 50 years, and we thought introducing new ultra thin coatings, coatings that are again better for the environment and more effective and so, so that was Our first kind of launch. Was protecting electronic parts, and our first customers were in aerospace. But again, that's kind of our sweet spot. We look for opportunities in industries that really haven't changed in 50 years or more.Jessica Owen

And so correct me if I'm wrong, but the way you guys work is that you go out looking for researchers and scientists who are making this technology and you collaborate with them, or do you actually make these technologies yourself, using your own knowledge?Cam Chidiac

So it's a combination of in house development, and then also we do a lot of technology licensing. What's I'm a huge fan of technology licensing and commercialization, and the main reason is there are hundreds of 1000s of new innovations issued patents from around the world, and 98% of them never get commercialized. Yeah, you know, a lot of people talk about how fast innovation is moving, and, you know, we're in this exciting time. I believe innovation is moving at a snail's pace. I'm I'm one of those people that I see a sea of opportunity. I see technologies that should be commercialized, that can help the greater good, and no one knows about them. They're stuck on a shelf. So one of the things we do, I think we're very good at, is, again, partnering with these scientists, looking for whether it's universities, national laboratories or independent companies, and maybe they're in a foreign country, like Japan, maybe they have no access to markets in the US. We partner with them, we launch the product and we commercialize it. Okay,Jessica Owen

so what do you think the reason is that a lot like I think you said, 98% of these things just never come to fruition. Is it maybe money, resources, experience. I mean, what do you think it is?Cam Chidiac

I think it's a combination of what's happened with the invention of the internet over the last, you know, 20 plus years. You know, we're kind of prone to looking at page one of Google search results and then not going beyond that, and people aren't looking hard enough, you know, we've kind of become lazy. And what's super what's been really interesting for me, kind of as an outsider, is how many of our global problems have already been solved, whether it's air pollution, whether it's PFAs contamination, micro, you know, micro pollutants. A lot of these issues have been solved, and we, we love to talk about the issues, and very few people are really researching and connecting the dots between, you know, academia, laboratory, research, and then commercialization. So So a combination of people just don't know, and then, and then the disconnect between either a large corporation or the right commercialization partners for the right technologies at the right time to bring it to market. So there's just a giant disconnect where I think creates a lot of opportunity.Jessica Owen

Well, I mean, it's it's obviously giving you a lot of opportunity in terms of your own company. So today, then I wanted to mainly talk about one of your newest innovations, called dry fiber. I understand that this is a fluorine free durable water and oil repellent textile finish. So when did you come up with this idea? And just tell me a bit more about it?Cam Chidiac

Sure. So Cornell, actually, Cornell University in Ithaca, New York, developed this technology and filed a patent for it back in 2016 and we had read an article about the technology, kind of very early on in their research, and having kind of dipped my toe into textile finishing with one of our other coatings a few years prior, I knew that there was a big opportunity in oil for oil repellency that was less toxic to humans, you know. P fast, free, so we started negotiations with Cornell and basically said, Hey, let's partner together. Let's start a new company. You know, you guys will be equity owners. Will be equity owners, and let's launch this in in partnership and get this to market. Okay?Jessica Owen

And so then that was back in 2016 so it's taken a few years. Then are you able to tell me anything about what the coating or finish consists of,Cam Chidiac

yeah, so it's patents published. It is a PDMS based chemistry. So PDMS is essentially a 50 way of saying silicone, polydimethyl siloxane. And PDMS has is used in foods, so as an anti foaming agent in oils. It's used in our milkshakes and smoothies. So it's, you know, very safe. It's an FDA approved organic polymer for food. The scientists at Cornell really took an innovative approach. They created a custom PDMS polymer. And what was interesting about their research was it it combined research from the materials science department at Cornell so led by Dr Emmanuel gianellis, he partnered. Up with Dr Jin to fan and Dr chi, who are experts in the textile industry. So Dr Dr fan is an Honorary Fellow of the textile Institute. His his whole body of research is on textile science. So he approached the materials science department of Cornell and they partnered together, hoping that they could kind of look at this problem of of oil repellency, using fluorine and try to fix it. And I think they did exactly, exactly that with a very innovative approach. And one of the main things they did was, okay, let's look at what oil repellency really is. And if you look under an electron microscope at the topology of the fibers that are classically oil repellent, you'll see a very specific structure, a very specific pattern on the fibers. So they, they, they, they knew that was their goal, try to create a fiber with that pattern that's durable, that's safe. And they did that, I think, very successfully.Jessica Owen

Okay, so this finished then, I mean, I've personally when all the sort of innovations that I've seen, a lot of people are trying to develop these fluorine through DWR because they are much safer and more environmentally friendly, and a lot of people have succeeded, but these tend to be only water repellent, and the oil side is a lot harder to achieve. And I think quite a few people have told me it's virtually impossible at the moment. So how have these guys managed to achieve that?Cam Chidiac

Yeah, again, I think they really took a step back and they said, Okay, you know, what are we trying to do here? Which we're trying to create a surface structure, a surface topology that we know will repel oils as well as water. And so that's when the experimentation started. And then they created again, this, this custom PDMS finish that's ultra thin. So the finish so it's not nano particle based, but the finish is extremely thin, which is great for hand. Feel, 100 nanometers, 100 to 200 nanometers thickness on the surface. So to give you an idea, a human hair is about 100,000 nanometers thick. So very, very thin, without, without using nanoparticles, but again, focusing looking at the problem from a different perspective, let's focus on the surface structure that we have to create to repel oils, and let's create a D, W, O, R, that, you know, we hope can, can perform as Well as per fluorinated chemistries.Jessica Owen

So this repellent, then, how effective is it? I mean, is it as effective as the more sort of less environmentally friendly chemicals?Cam Chidiac

Yeah. So for water repellency, we are excellent. So we are super hydrophobic, so we are a super water repellent. We've tested a range of different fibers, from natural to synthetic. And you know, we have a really nice, durable water repellent finish on the oil repellency spectrum. We are okay, but so we're at a between a two and a three on the oil repellency rating system based on the aatcc standard. So for industrial purposes, this is not a good product, but for the apparel industry, for active wear outerwear, you know, we have enough performance so everyday oils, we can repel everyday oils very effectively. We have great durability. But again, for industrial purposes, you know, if you're an oil worker, working on a tank or somewhere, and you have this really rugged work where, unfortunately, they're still using PFCs. And we're not there yet, but, but definitely for outerwear in the apparel industry, we've got a great product.Jessica Owen

And what do you mean by natural oils, then, is if things like, maybe, oh my gosh, I don't know, the oil that you might have in your own head, the natural oils, that kind of thing,Cam Chidiac

so more everyday oils that will encounter. So cooking oils, oils that are in mayonnaise, olive oils, you know, things, things like that. It repels them very effectively. So, you know, there are some apparel companies out there that make. Are cotton pants that are, you know, stain repellent. I won't name names, but you know, we know that company and they are working to to get PFAs and perfluorinated chemistries completely out of their supply chain. But you know, when you do that, there's a predicament, because then you can't have normally, you can't have oil repellency anymore. So I think that's where we kind of, we kind of fit in.Jessica Owen

So I imagine the market and the demand for this is quite high, if you have many inquiries about it. I mean, I know that you guys have only really recently just launched this, but have you had quite a lot of interest inCam Chidiac

it? Yeah. So what's been really interesting for us is all the interest from the food packaging industry. From the fashion side, we've had a huge amount of interest, and we're negotiating with over 20 large apparel brands to begin pilot testing in the fall. But on the food packaging side, which I never imagined, because I had no idea that fluorinated chemistries were used in our food packaging. On the food packaging side, we've had a huge amount of interest as well, which prompted us to start looking into that industry and try to understand, Okay, what's going on in the food packaging area. They're using the coatings in our the wrappers for our burgers and fast food places, in pizza boxes, in popcorn. And what's happening is, unfortunately, microwave popcorn. What's happening is when we eat that popcorn, they found, or we eat that burger, they found that the perfluorinated chemicals, the PFAs, leeches into the food we eat, and then we eat it, and it gets into our body. And the problem with these, they're called, quote, unquote, forever chemicals is that they never break down. So as As humans, we are consuming these toxic chemicals even today. So they still haven't been banned globally in food packaging to this day. So from pizza, you know, the main main applications are pizza, you know, fast food, burger wrappers and then microwave popcorn. But you know, it's a PFAs is a huge issue, and the use of fluorine in these food and food packaging is even more dangerous than the fluorinated chemistries that are being used in textile finishing. So because it bioaccumulates in our body, it's been linked to a range of different cancers, which is proven it's in our drinking water, it's in our ground water. So we're kind of, we're absorbing all these harsh chemicals, but people just don't know. I mean, I didn't know, you know, I didn't know exactly. And it's, you know, it's very troubling and and once you start reading about it, it gets even worse. There was a great film that just came out a few months ago called dark waters, which was all about this big Hollywood production, and was all about this issue, and I think it's educated a lot of people, so that was a long way to answer your question of we've had a tremendous amount of interest. And interestingly enough, not only apparel, but also food packaging. No,Jessica Owen

that is very interesting. I mean, obviously I know a lot more about it in terms of textiles, but it's quite eye opening to think that these, these chemicals, are getting into food packaging and into our bodies, and it's just mad to think that they haven't been banned yet. It's just, it just seems silly not to but there we are, wellCam Chidiac

and good, good news for you, as Europe is is ahead of the game and starting to ban these things. But now the issue is, how do we get it out of our environment? Because it's been there since the 1940s and because, you know, the food we eat has it inside it. So if you're eating fish, for example, it's in the fish that you consume. So it's, it's all around us. But again, I think, I think Europe taking the lead is is helping, but I think it has to be a much, a much greater ban on PFCs.Jessica Owen

I think, yeah, if you're going to do anything significant to make a change, then you just need to be a bit more cutthroat about banning these chemicals. But, I mean, what's your opinion? How do you think we can do that? Is that just a matter of lobbying and taking these sort of findings to, I don't know, big institutions that can do something about it. I mean, how do you even start to tackle a problem like that? YouCam Chidiac

know, I think organizations like Greenpeace have done a. A very good job of calling out large corporations that use these forever chemicals in their products and as a result of their pressure of them educating the public on the risks between forever chemicals and and their lives and their and their health. So so I think more of that, more education for the population, for people to fully understand that we are being contaminated on a daily basis, and we need to, you know, continue to apply pressure, both on the legislative side and then also to these to these brands that we support.Jessica Owen

So moving on then this dry fiber innovation you have just recently been accepted onto this year's fashion for good accelerator program, which is the ultimate sort of program for startups driving innovation in sustainability, circularity and transparency, to make fashion good and to make the industry a bit more sustainable. So how's that been for you guys? I imagine you must be pretty pleased with yourselves.Cam Chidiac

Yeah. So we're honored to have been selected for this year's fashion for good program. It's really been incredible. So far, their team is excellent. And really for us, you know, having access to industry experts, having being able to speak to large brands openly about their goals, that you know, in our case, understanding the current chemistries they're using, how we could possibly fit in, but really that industry knowledge, I think, is key, because we come from aerospace coatings, we don't come from the textile industry, and being able to ask questions, get feedback has been really great. So so far, we're very, very pleased with the program. AndJessica Owen

I think I also read on their website that obviously, at the moment we've got Coronavirus going on, and I think they, I don't know if they think they chose the finalists like virtually or something like that. So how is the program working at the moment?Cam Chidiac

Yeah, so the program is completely virtual, the first ever completely virtual fashion for good accelerator. And you know, we've gotten used to it. We just went through an intense week of virtual meetings. But you know, I, you know, I think you have to adapt to your everyday circumstances, and COVID 19 has definitely changed things but, but again, they've done a great job of creating this open virtual environment for us to ask questions, talk to brands and kind of discover one another's interests and and and line our ourselves up, hopefully for the future, for pilot programsJessica Owen

while we're on the subject of Coronavirus. Then how has that affected your company? Are you? I imagine you're all working remotely, or how's that all working for you?Cam Chidiac

Yeah. So for us, all of our testing has been slowed down, so Cornell University was shut down. The labs at Cornell were shut down so we can't get samples out right now and then, we had scheduled seven or 8/3 party lab tests for our chemistry, including green screen, and then a bunch of durability testing, abrasion testing, repellency testing, and so all of that is on hold because the labs we work with are locked down. So for us, it's really affected our timeline. But I think long term, it's not, it's not going to really affect us. I mean, the textile industry will continue, and we'll be ready for it, hopefully, to start doing pilots in the fall.Jessica Owen

And well, actually, I imagine this is somewhat going to help you guys, because I think I've spoken to people, and they've mentioned that sustainability is something that is on people's agendas even more now, considering Coronavirus and trying to look after ourselves and the environment. So actually, maybe more and more people are going to become interested in what you guys have to offer.Cam Chidiac

Yeah, we hope so. And you know, at a minimum, I hope it, it shines a bright light on the PFCs and perfluorinated chemistries, and fluorine and the Association of these forever chemicals with illnesses that have been rising over the last 50 years. And I said this, I've said this publicly before. It's very interesting to. At the rise of cancer in the last 50 years, and then the rise of perfluorinated chemistries in the last 70 years. And you kind of line those graphs up and and there's a direct correlation. So, so, yes, we hope, we hope that this will shine a bright light on safety, safer chemistries in the industry moving forward.Jessica Owen

So Coronavirus, there must have been one of your biggest challenges to deal with to date. And what other sort of hurdles have you had to overcome since launching, launching the brand as a whole, actually,Cam Chidiac

so when we first started at Cornell, the technology was solvent based. It was multi step, and we knew that it wasn't commercially ready, especially for the apparel industry. So for the last two and a half years, we've worked with the Cornell scientists to take it from a multi step solution to a single step, water born solution, where we can ship concentrate to mills around the world. So from a product perspective, that transition was very difficult, very challenging on the scientific side, but now we're there. We've made that transition. So so as far as product development, I would say that's that's been the biggest challenge.Jessica Owen

And then, on the flip side, what have been your biggest success? I'm guessing it might be this accelerator program.Cam Chidiac

Yeah, so, you know, very, very happy to be part of this new accelerator program. And again, taking, you know, being able to take a laboratory technology, something was developed in a laboratory, and expose it to brands and corporations that could use and they could use and implement it, so that we're, you know, we're very passionate about that commercialization bridge of going from lab to factory and and again. Fashion for good being helping us with that vehicle of just being able to promote our technology to key stakeholdersJessica Owen

has been great. And so finally, then cam, I wanted to ask you about some advice that you might give other people trying to start up a company within this type of industry. I mean, I know that you guys have been around now for about six or seven years, but what advice would you have to people who are trying to start out? Yeah,Cam Chidiac

my advice is, study the industry that you're getting into. You know, in some cases, the startups have founders who come from that industry. In my case, I came from aerospace, so I didn't know anything about the industry. And one of our challenges is, is really, you know, especially an industry like the textile industry that's been around for 1000s of years, you have to really study it. You have to align yourself with your customers goals. You have to understand pricing, you have to understand logistics, supply chain. So really, really study the industry you're getting into. You know, I'll give you one quick example. There was a large apparel brand a few years ago that was interested in another textile coding that we had started to promote. And they agreed to do a pilot with us in China, and they connected us with their mill in China. And we started talking to their mill in China, and we said, hey, we're ready to ship, you know, the products here in the US. And they said, Great. And they tried the mill in China, tried to import our chemistry into China. Not even the mill knew that they needed a special import license to get the chemical in, and as a result, it completely messed up our project. But again, you know, if we had been in the industry, maybe we had known that, and we could have, we could have taken steps to to make sure that the partner on the ground had a chemical import license. I mean, there are small details like that that can derail a startups, you know, potential or pilot project, and again, do as much research, talk to as many industry experts as possible, so that that doesn't happen. You know, those kinds of things don't happen. I think is essential.Jessica Owen

Well, I think that's wise advice. But on the same side, I guess the longer you do things, the more you learn, and these things will just start to become second nature. So I guess it's just that experience as well, really, absolutely, well, Cam, I mean, it's been lovely having you on the show today, and it's been really interesting to listen to your company how you started out. And I think it's really quite eye opening to learn that over 95% of these sort of ideas just never actually get to the table. So, I mean, I really. Hope that more companies like yours sort of start to sprout up, and we see the see these ideas come to life. So thank you very much for talking to me, and good luck with the accelerator program as well.Cam Chidiac

Thank you so much. Thanks for having us.