Sponsored by ZAITEX

Today, saving time and energy is a priority, especially in production processes requiring a great amount of both. In the textile industry, you may include processes involving huge dyeing machines such as over-flow, jet or autoclave systems.

Nowadays, news reports say emergency interventions will be drawn up to try to stem the impact of surging prices for power and natural gas on industry, businesses and households. So just being aware that small measures in energy saving will be strongly significant in the near future means a lot.

For almost five decades, ZAITEX has helped textile dyeing plants, laundries and fabric manufacturers apply eco-friendly, certified dyes and auxiliaries. The motivation is, and has always been, to optimise production performance for customers. To help customers cope with the challenging task of reducing overall energy consumption, ZAITEX has an efficient idea impacting a specific step of textile dyeing production: the bleaching of cotton.

The process of bleaching cotton involving hydrogen peroxide (H2O2) is conventionally carried out under high temperature and strong alkaline conditions.

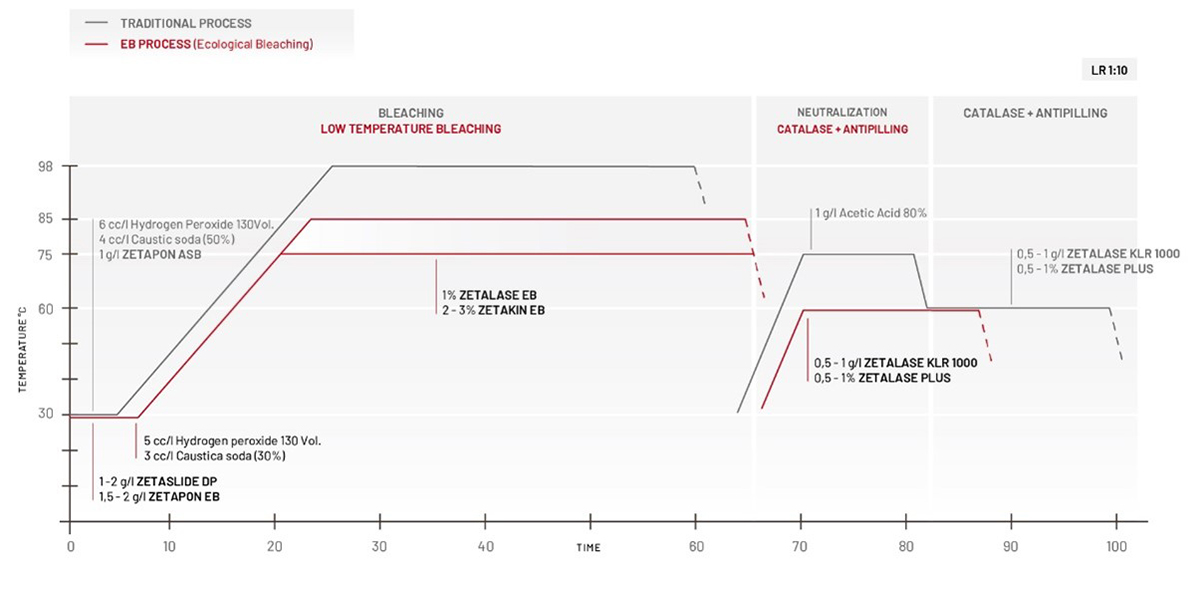

ZAITEX’s textile technicians developed a low temperature cotton bleaching process called the EB Process. It is designed to allow the discontinuous bleaching with hydrogen peroxide of cellulosic fibres and blends with elastane. It boasts a maximum range of working temperature between 75°C and 85°C and a neutral pH of the bleaching bath.

The EB Process consists of an enzymatic system that allows the simultaneous degradation of pectins and natural pigments that are present on the cotton fibres.

The combination of two auxiliaries called ZETALASE EB and ZETAKIN EB is the core of ZAITEX’s EB Process.

ZETALASE EB allows the obtainment of articles characterised by soft, full and natural hand. It features lower creasability, better sewability, strength and elasticity. It leaves the material with its natural soft touch and at the same time gives optimal hydrophilicity to the textile substrate.

Meanwhile, ZETAKIN EB is an adjuvant activator of the reaction of hydrogen peroxide in discontinuous bleaching of cellulosic fibres free from heavy metals.

They both have to be applied together with ZETAPON EB – a combination of wetting, detergent, dispersing and sequestering agents. It regulates, with a single and easy dosage, the development of the hydrogen peroxide, chelates calcium, magnesium and iron ions, conferring thanks to its high wetting-detergent action, very good penetration in the bleaching bath inside the fabric and therefore allowing a strong extractive action of the different impurities. It does not generate foam.

Another key point of the EB Process is the final pH of the bath, which turns out to be neutral or slightly acidic. This avoids an additional rinse to neutralise the bleached cotton with a substantial saving in terms of energy, water and time consumption.

To sum up, the EB Process achieves several advantages for cotton fabric, such as:

- Soft hand

- Acceptable white degree for pastel tones

- Reduction of bleaching time

- Lower weight loss of the material

- Lower loss of resistance

- Lower energy consumption

- Time, temperature and water saving

- Low alkalinity in effluents

The EB Process has already been tried-and-tested in several production plants, highlighting crucial advantages in reducing the bleaching time. For instance, less time required to complete the process thus saving energy and increasing production efficiency and less damage to the fabric by limiting creasability and loss of fabric resistance.

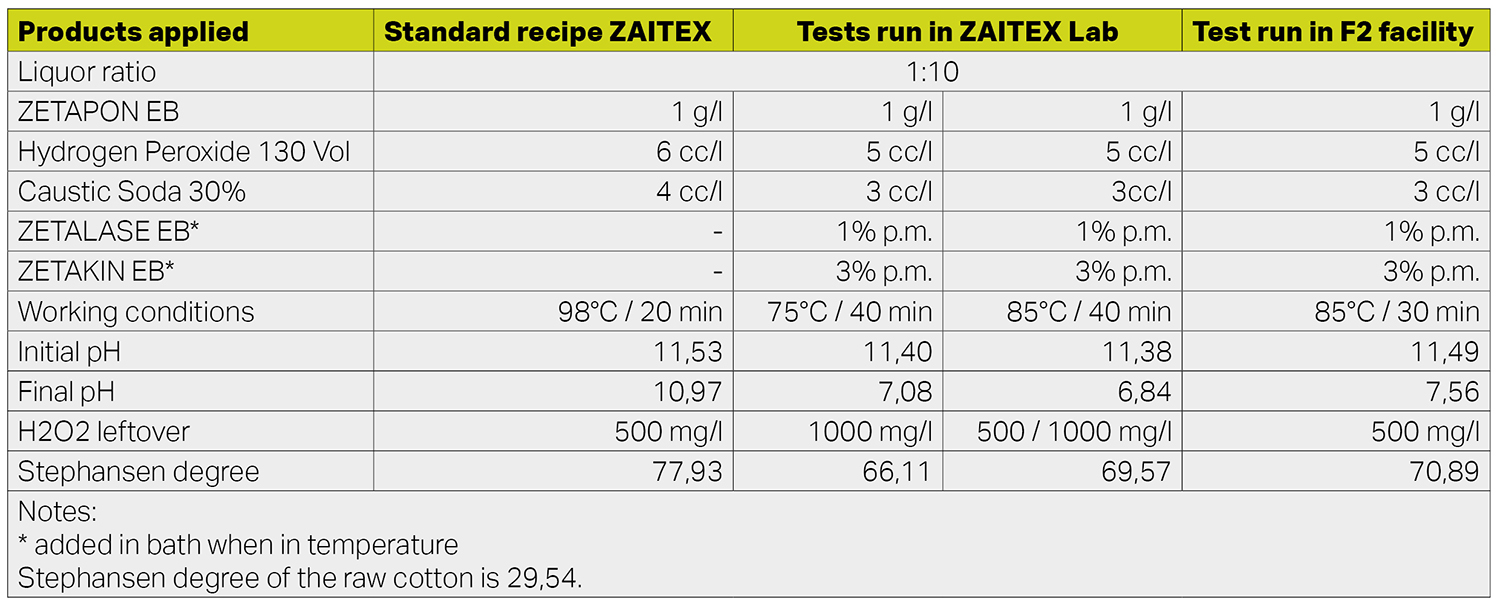

The study ZAITEX technicians conducted is aimed to highlight all those features above. Several tests have been run in different situations in order to compare each result. Considering the outcome derived from the application of a standard bleaching recipe, which the lab technicians are used to following as a reference, the study makes a standard raw cotton fabric, bleached according to several conditions, as stated in the table below.

The study includes three other tests: two of them were run in ZAITEX labs, one at the minimum suggested temperature of application of the EB Process (75°C), the other one at the maximum temperature (85°C). The last test was run in a small dyeing machine used for pre-production trials.

The use of this latter machine was gently granted by ZAITEX customer F2 Lavorazioni Tessili, a textile finishing company highly experiences in the dyeing and finishing of natural and man-made fibres, located in Schio Italy.

Carrying out a test in a dyeing plant is the best way to measure how effective the lab tests are.

All test results lead towards an acceptable degree of white of the bleached cotton, plus it is easy to notice that the pH of the bleaching bath turns out to be slightly acidic. This value demonstrates that it is possible to avoid an additional rinse to neutralise the bleached cotton.

Tests conducted in ZAITEX labs conclude, as does the one carried out in F2’s facility, that the EB Process enables an acceptable degree of the white on bleached cotton. Benefits include saving water and energy by removing the need for an additional rinse and enabling a lower working temperature.

Considerations

Let’s briefly comment on the data in Table 1 and focus on the results deriving from the standard recipe and from the test of EB Process conducted in the pre-production machine in F2’s facility.

On one hand, values of estimated hydrogen peroxide leftover suggest a similar result for both tests.

On the other hand, out of the two, the recipe applied in F2’s facility turns out to require less time and has a lower pH value of the bleaching bath. This does not indicate there would be a higher development of hydrogen peroxide and thus the chance to avoid an additional neutralising rinse.

Despite a higher Stephansen level of whiteness value in favour of the standard recipe, we might all agree that it does not mean the bleaching process results are far better due to the several factors involved in the evaluation. For instance, the hand of the fabric or its resistance capability.

Since almost any process has to be fine-tuned, case by case, ZAITEX is focused on the R&D activity for the best performance in the preparation, dyeing and finishing of mostly any kind of textile fibre and for the majority of the production processes. An ideal partner to choose for those manufacturers that seek reliability and knowledge for industrial textile application.

For more information, visit www.zaitex.com.

Have your say. Join the conversation and follow us on LinkedIn