Sponsored by Konica Minolta

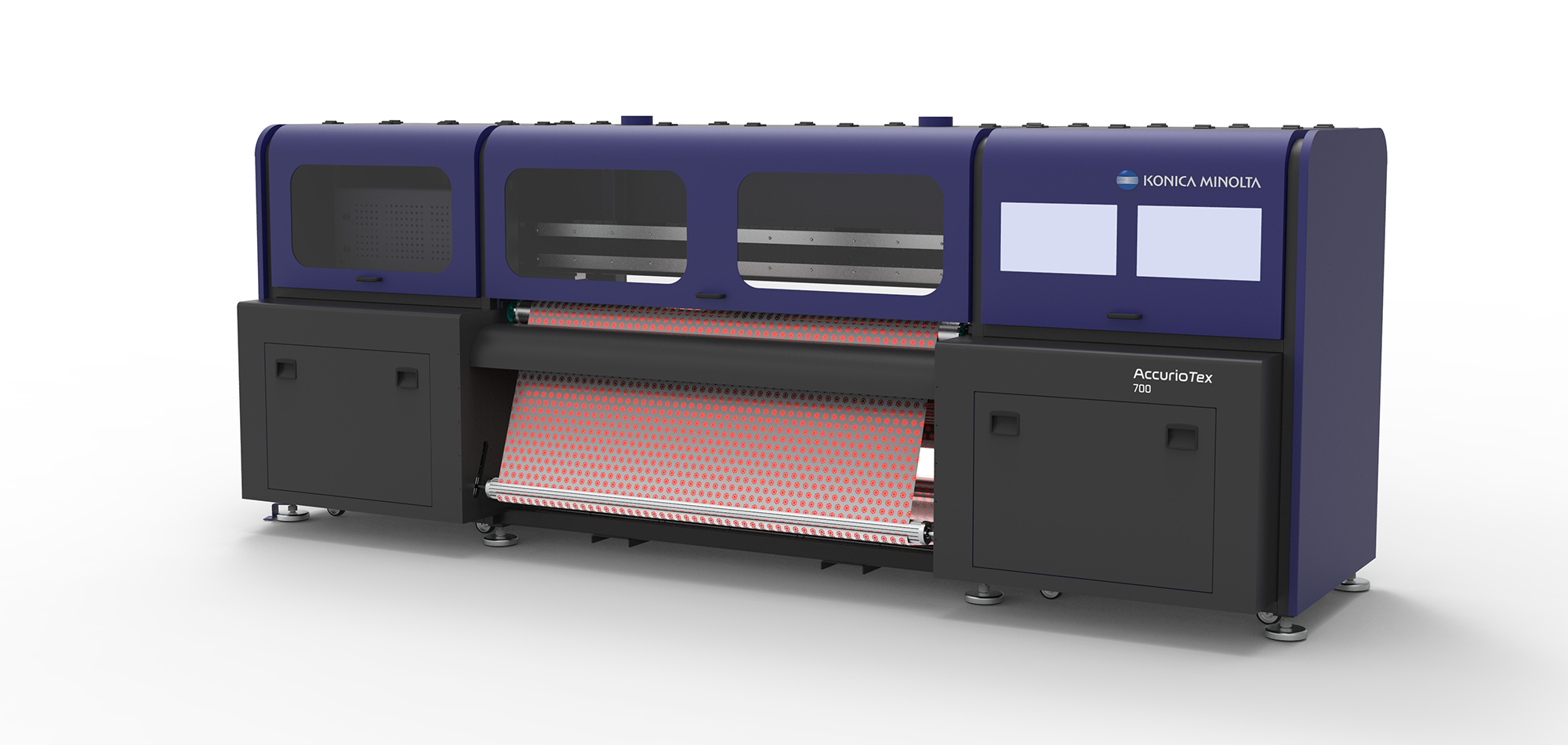

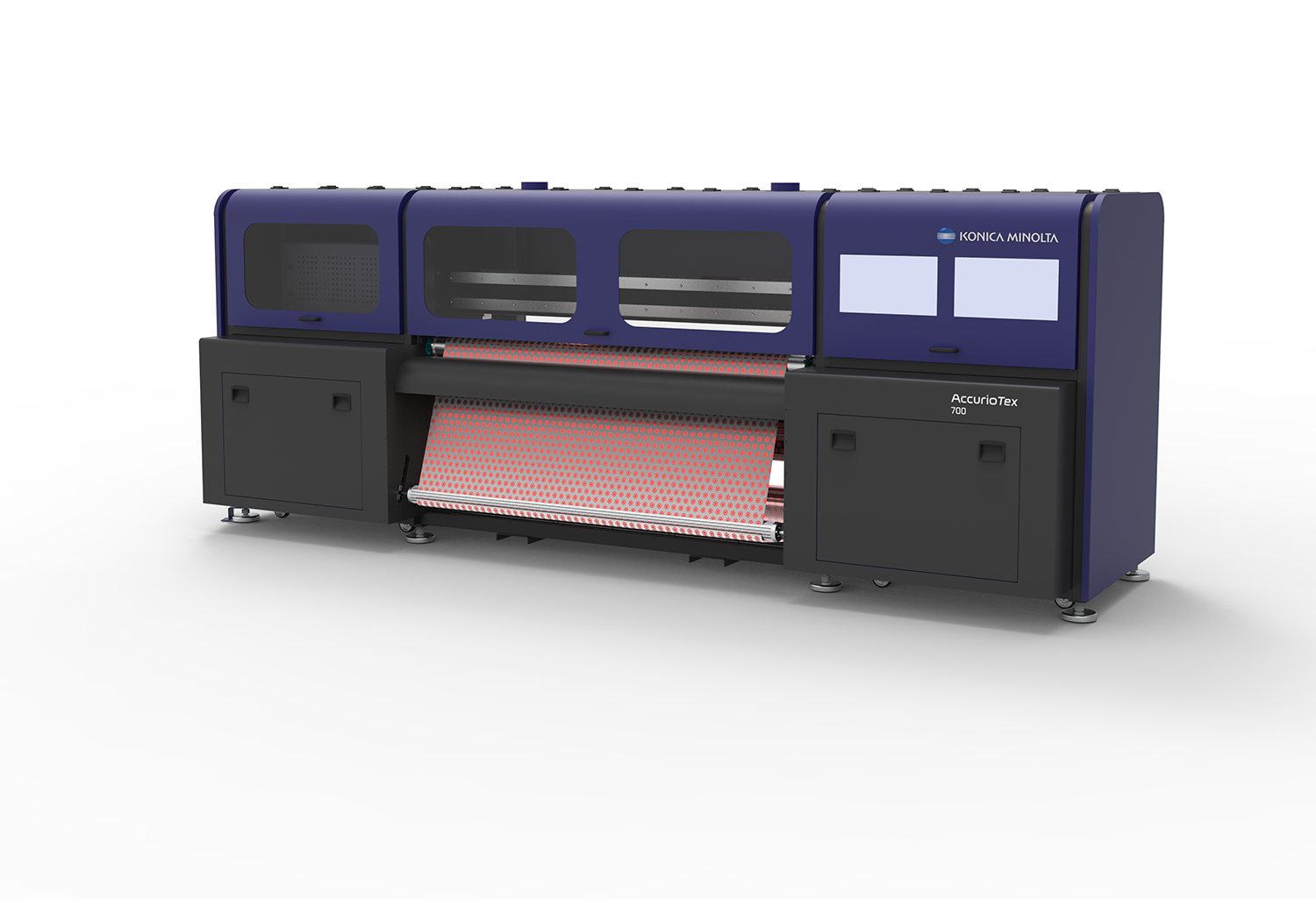

Technology OEM Konica Minolta launched its AccurioTex 700 dye-sublimation digital textile printer at this year’s ITMA exhibition in Milan in June.

The AccurioTex 700 is the first digital textile printing machine from the Japanese manufacturer that uses sublimation technology on transfer paper for prints without carpet. The machine is equipped with variable drop technology that allows better print resolution and colour brilliance. The system offers flexibility, durability and reliability of components, adapting perfectly to the individual needs of market players, according to Konica Minolta. This will allow professionals in the sector to achieve a lean production process and reduce costs, without sacrificing quality.

The AccurioTex 700 is a 2m-wide transfer paper dye sublimation printer that brings Konica Minolta into a new sector. This means for the market, small footprint and high quality with an energy saving sublimation printing system easy to use and maintain, the company says.

On the decision to enter the dyes-sublimation market, Gianluca Macchi, global sales manager Konica Minolta Italia, Textile Division, explains: “Sustainability is now becoming a central theme and a mission to achieve for every player in the textile industry. The focus is on environmental, eco-toxicological and economic sustainability. Konica Minolta has been included in the list of the ‘2023 Global 100 Most Sustainable Corporations in the World’ and received a GOLD-level recognition medal in the EcoVadis Sustainability Ratings for 2023.”

He continues: “Our solutions are recognised worldwide as highly reliable and durable products. We develop our printers, inks and print heads using our proprietary technology. Thanks to these unique sources, we provide complete customer assurance through a unique interface and exceptional technical service.”

Accuriotex700 is equipped with variable drop technology that ensures a better resolution and colour brilliance. With 16 new native four-colour print heads, it is a high quality and high precision device.

What’s more, the AccurioTex700 is a flexible system, with durable and reliable components that can be customised to different needs and production volumes. It uses 16 of Konica Minolta’s variable drop size print heads and CMYK inks to offer print speeds of up to 190sqm/h in draft mode (100/130sqm/h in a choice of standard modes and 50 in the top quality 720x720dpi mode).

Like similar dye-sub machines, it is suitable for producing a range of polyester-based applications including fashion fabrics, furnishings, sportswear, outdoor and technical fabrics, soft signage, flags and banners.

Konica Minolta’s marketing division director, Alberto Seteffenini, admits the company is a latecomer to this sector but explained that with its addition to the more industrially-focused Nassenger line of direct-to-fabric printers, the new machine would get customers of the latter “outside these areas, and bring more opportunities”.

Konica Minolta textile printers are backed by Maestro production management software that monitor the entire textile printing/decoration process from end-to-end, which may include that status of steaming and pre-treatment processes where relevant. Control status and waste output information can be gathered via Industry 4.0 connections with equipment upstream and downstream of the printer.

AccurioTex 700 will help professional printers to rethink their production. For Konica Minolta, ‘Rethink Textile Printing’ is not just a slogan, but rather a way of living and thinking: it is an invitation to stop doing things as usual, or as they have always been done and go further by pushing oneself to think outside the box. This is a way of successfully adapting to the ever-changing market.

Enrico Verga, Inkjet Textile director, Konica Minolta, says: “We are a company that has been in existence for 150 years and if we had not learnt to adapt we would not still be here trying to improve. It is a global campaign to 'rethink print possibilities' in the case of textile printing processes to look for and create solutions that are environmentally friendly and can create efficiencies in the printing and fabric creation processes.”

For more information: www.konicaminolta.it

Have your say. Tweet and follow us @WTiNcomment