Sustainable innovation from Taiwan at Techtextil

-By Madelaine Thomas, Lorraine Mullaney

Sponsored by Taiwan Textile Federation (TTF)

The Taiwan Textile Federation (TTF)’s Textile Export Promotion Project will be displaying the country’s cutting-edge sustainable and functional textile technology at the upcoming Techtextil tradeshow in Frankfurt from 23- 26 April.

Taiwan’s textile industry has a strong focus on developing functional and green fabrics and stakeholders are continuously transforming, upgrading and actively engaging in innovative R&D. TTF will be showcasing some of the latest developments at the Taiwan Pavilion, from recyclable high-elastic industrially washable polyester fabric for the aviation industry to high-visibility yarn for sports and outdoor clothing.

Since the EU has proposed more stringent environmental regulations for the textile industry, sustainability has risen up company agendas. Techtextil and Texprocess reported that 96% of Techtextil trade visitors and 97% of Texprocess visitors said sustainability would play a key role for their business in the next three to five years.

The Taiwan Pavilion will be showcasing functional fabrics for the aviation, marine, and healthcare industries from the Advance Hitech Textile International Corporation. The company will be informing the show’s visitors of the benefits of its ECOlastic™ product: an innovative polyester fabric that is designed to be recyclable, industrially washable, highly elastic and with high visibility in mind. The technology has been made from recycled polyethylene terephthalate (PET) and bio-based super-elastic PET fibre, which has undergone appropriate fabric structure design and professional dyeing and finishing processing. These mono-material fibres can be recycled simultaneously to meet the regulatory requirements of upcoming EU regulation, which will enforce circular economy processes for textile firms. Visit Advance Hitech Textile International Corporation in Hall 12.1, Booth D05.

Also focusing on environmentally friendly products is Taiwan-based woven fabric manufacturer Honmyue, which will be showcasing its Ecotech range in Hall 11.1, Booth E51A. This is comprised primarily of nylon and polyester sourced from various recycled materials, such as PET bottles from landfills and oceans, scraps, discarded greige from textile factories, fishing nets from the ocean, industrial GHS from steel factories, and used apparel from customers.

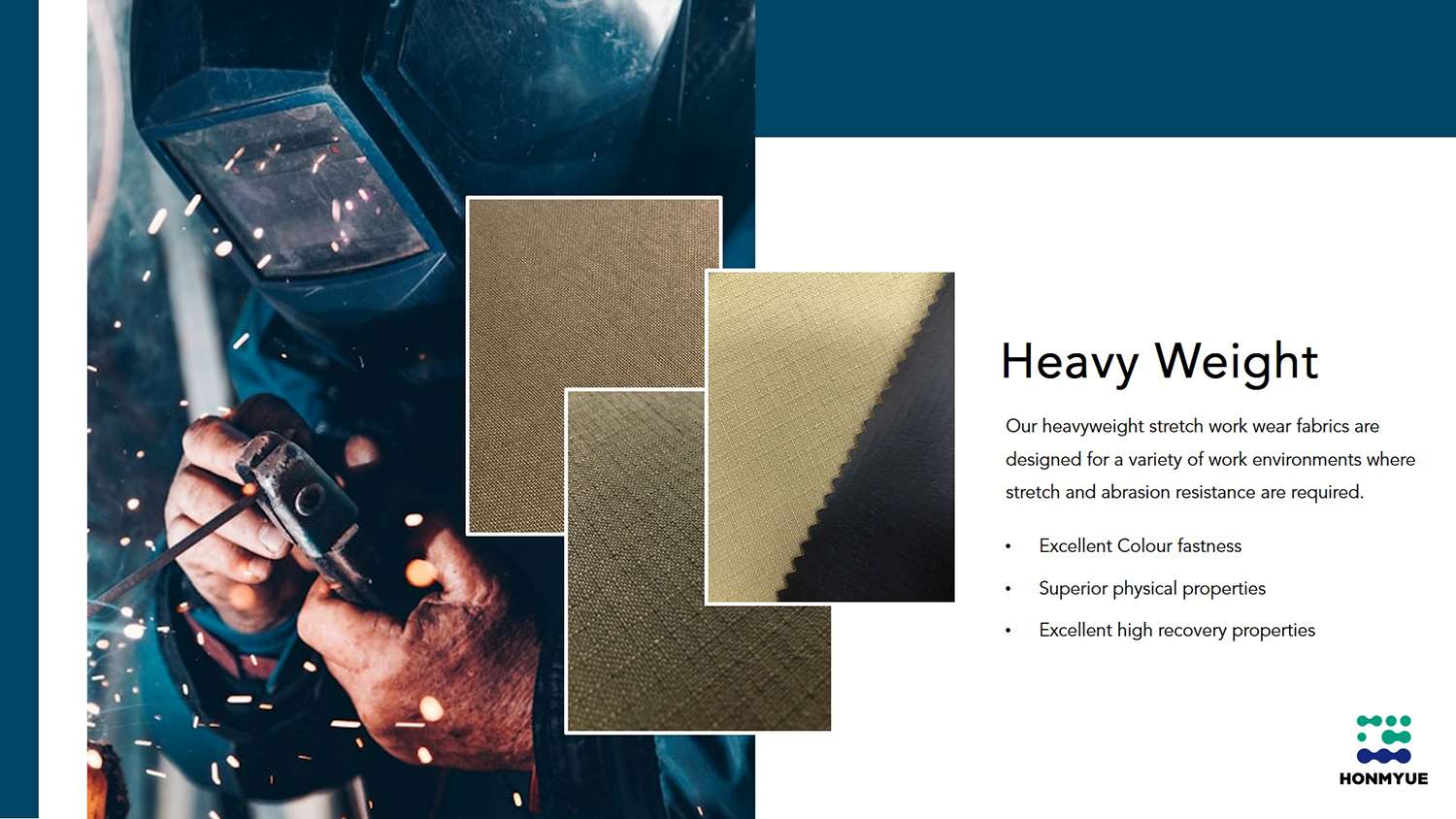

The company will also be highlighting its flagship product series of heavyweight stretch workwear fabrics, which have been tailored for diverse work environments that require garments with stretch and abrasion resistance.

Also in the industrial fabric business is U-Long High-Tech Textile Company, which manufactures a wide range of functional and sustainable fabric, including wovens, knits and laminates suitable for apparel, protection and industrial use. Its collection includes high tenacity, inflatable waterproof, anti-abrasion and fire-resistant fabrics, among others. Find out more in Hall 11.1, Booth E71C.

Functional textile specialist Nam Liong Global (Hall 11.1, Booth E61A) will be exhibiting its high-polymer materials including GRS, bio-based, thermoplastic polyether ester elastomer (TPEE), functional membranes and lamination fabrics as well as mono-material solutions, neoprene, anti-cutting and abrasion fabric and hook and loop textiles.

M&H Innovation will be highlighting the benefits of UltraCluster: a more eco-friendly recycled synthetic fibre that has been certified to Global Recycled Standard (GRS). The product is designed to be an excellent thermal insulating filler and the company claims the polyester fibre has the closest down cluster structure of any fibre ball structure. It is also said to retain a large amount of air, which provides excellent warmth and maintains a balance of thermal comfort for the body. Find out more in Hall 11.1, Booth E51A.

Meanwhile, temperature regulation has been the focus of recent innovation for Taiwan’s Universal Textile Company (Hall 11.1, Booth E51E), which makes yarn and fabrics for sports, outdoor and lifestyle clothing. Its R&D department has been adopting Unified 3D Material: a 3D fabric system designed to simulate fabric’s physical and texture properties to create visual alignment between applications.

Blended with recyclable long fibres, universal green wool has been designed with temperature regulation ability to keep the body dry and odour-free – it has also been designed to keep the wearer warm, even if it is wet. Soft to the touch and not itchy, it can both absorb and repel water and has extremely low flammability.

The focus for Yuang Hsian Metal Industrial Corp’s R&D, though, is antimicrobial functionality. The company will be highlighting the benefits of its AB65 aqua bronze alloy yarn for textile applications in Hall 11.1, Booth E61B.

This aqua bronze alloy material was developed using a special alloy made from six pure metals and five elements through continuous testing and refinement, resulting in a durable and versatile material that is ideal for a wide range of applications.

The company reports that the AB65 yarn was awarded the Cu+ certification from the International Copper Association for its antimicrobial properties in 2014. AB65’s antimicrobial and anti-biofouling properties make it ideal for use in marine aquaculture nets, where it can help to reduce the release of plastic micro-particles into the environment.

The product has been designed for use in a wide range of textile applications, including socks, gloves, underwear, protective gear, woven and knit fabrics. It is equipped with several functional properties, such as antibacterial, mildew-proof, conductive, far-infrared, launder ability and antistatic. The company adds the solution is environmentally friendly and one of the most versatile materials on the market.

Partnering with other professionals is the goal of spinning and texturising specialists Chain Yarn Co, which is hoping to talk to professional fabric mills around the world at the show. The company’s goal is to expand its range of circular knitting fabrics as well as tricot fabrics and dyeing technology. It provides a comprehensive range of single jersey, double interlock, and jacquard products, including DURA-FILA® high-tenacity yarn, GREENLON® Eco-friendly yarn, SUP-LITE® super light yarn and Fun-Max® functional yarn. The company is exhibiting in Hall 9.1, Booth E59.

It’s not just fabric manufacturers who are focusing on sustainability. Eco-friendly equipment manufacturer Fulltide is also hoping to connect with visitors to highlight what it can offer in terms of vertical services – from development, dyeing, equipment treatment, and functional finishing. It aims to be the greenest production manufacturer of equipment for industrial fabrics. Find out more in in Hall 11.1, Booth E61E.

To discover more, visit the Taiwan Textile Federation and its member companies in Hall 11.1, Booth E51A at Techtextil. And, explore the TTF digital showroom before or after the event to delve deeper into Taiwan's textile industry.

For more information contact Mike Wang: swmike@textiles.org.tw.

Ad. by TITA

Have your say. Tweet and follow us @WTiNcomment