Sponsored by Taiwan Textile Federation (TTF)

Ad. by TITA

Taiwan-based functional textile expert GrandeTex talks to WTiN about its patent-pending technologies and sustainable material innovation for the sports, outdoor and workwear apparel industries.

With conventional materials under scrutiny from sustainability experts, many material providers and textile professionals are looking to develop more environmentally friendly solutions for brands and apparel manufacturers.

Taiwan-based functional textile expert GrandeTex has evolved its business model from fabric supplier to brand partner and fabric developer and producer over the last 14 years. With its patented technologies, the company provides functional fabric to the apparel, functional sportswear, athleisure, urban, workwear, uniform, outdoor and sporting goods industries. Innovations include making fabric that includes recycled polyethylene terephthalate (PET) content and turning agricultural waste into biodegradable fibre.

RICH-y®

One of the company’s recent innovation technologies is its RICH-y® yarn. The company developed the yarn in 2020, from a blend of Rich Nylon, Rich Polyester and ECO RICH-y®, using recycled PET material. It has permanent functionality, such as anti-bacterial properties, strong UV resistance, anti-odour and wicking functions. “Most functional properties are added after the yarn has been formulated, and the after-treatment can be washed away. For example, after 20, 30 washes functionality can be reduced,” says Tony Hsieh, senior sales director, GrandeTex.

He continues: “Around three years ago, our R&D department started to work on creating something different. We added all the functional elements into the fibre – such as moisture management UV resistance and then the cooling and thermal properties – so that the function can be permanent.”

This is one of the company’s innovation fabrics. Through the core technologies, the company has created more than 100 knitting and weaving patterns. These have already been integrated into product lines in workwear, outdoorwear and sportswear.

For the seasonal collections from summer to winter, the cooling element can be changed to a thermal element by giving the fabric a lighter weight and softer feel. The natural properties and comfort offered by this yarn make it a great option to be used in the base layers of sportswear, activewear and athleisure.

The product’s durability comes from the fact that functional elements are added into the fibre itself, rather than as a finish or coating. Hsieh explains: “Usually in functional textiles, function comes after treatment but with this treatment process can be washed away. With 20-30 washes function will be reduced.” With the way the function has been added to RICH-y® yarn, the function is permanent, says Hsieh – and the Recycled RICH-y® is a good option.

DOPE DYED

Sustainable DOPE DYED is an energy-saving and environmentally friendly material. Traditional piece dyeing process – a common step in the textile industry – has caused significant impact on the environment. Large amounts of chemicals and dyes are used in the dye processing, which leads to more water usage.

DOPE DYED reduces the pollution and wastewater discharges in a textile processing factory to the environment. It also reduces greenhouse gas emissions and water consumption and uses fewer chemicals. This enables direct savings on production costs and a substantial reduction of the ecological footprint of the final products.

“By adopting the dope-dyeing process, we must reduce the emissions of chemical waste that causes environmental damage. To put it simply, we must love and care for the earth that we live on,” says Hsieh.

Graphene

Graphene is known for its durability – amongst other qualities. It is often referred to as the “material of the future” because of its multiple applications in different sectors. Its diverse properties include high thermal and electrical conductivity, elasticity, toughness, lightness, and resistance.

The material is made of a single, or a few, layers of carbon atoms which are extremely strong and flexible, as well as being electrically and thermally conductive. When combined with other materials, it imparts these qualities to them, adding additional functionality that has applications in the sportswear, workwear and healthcare sectors.

For example, graphene’s temperature conducting qualities can be used to develop fabrics that soothe muscles and control temperatures, which is useful in both the healthcare and sportswear industry sectors.

Grandetex has been working with graphene textiles that combine the substance with polyester and nylon to give fabric more long-lasting functionality. These textiles also increase comfort for the wearer by regulating core body temperature during exercise.

“Graphene is big business,” says Hsieh. “Grandetex has been working with it in various capacities and we will continue to do so.”

Secao®

Grandetex has also been applying its expertise to innovating for more sustainability, as well as functionality. For example, it has developed a biodegradable yarn from locally sourced agricultural waste.

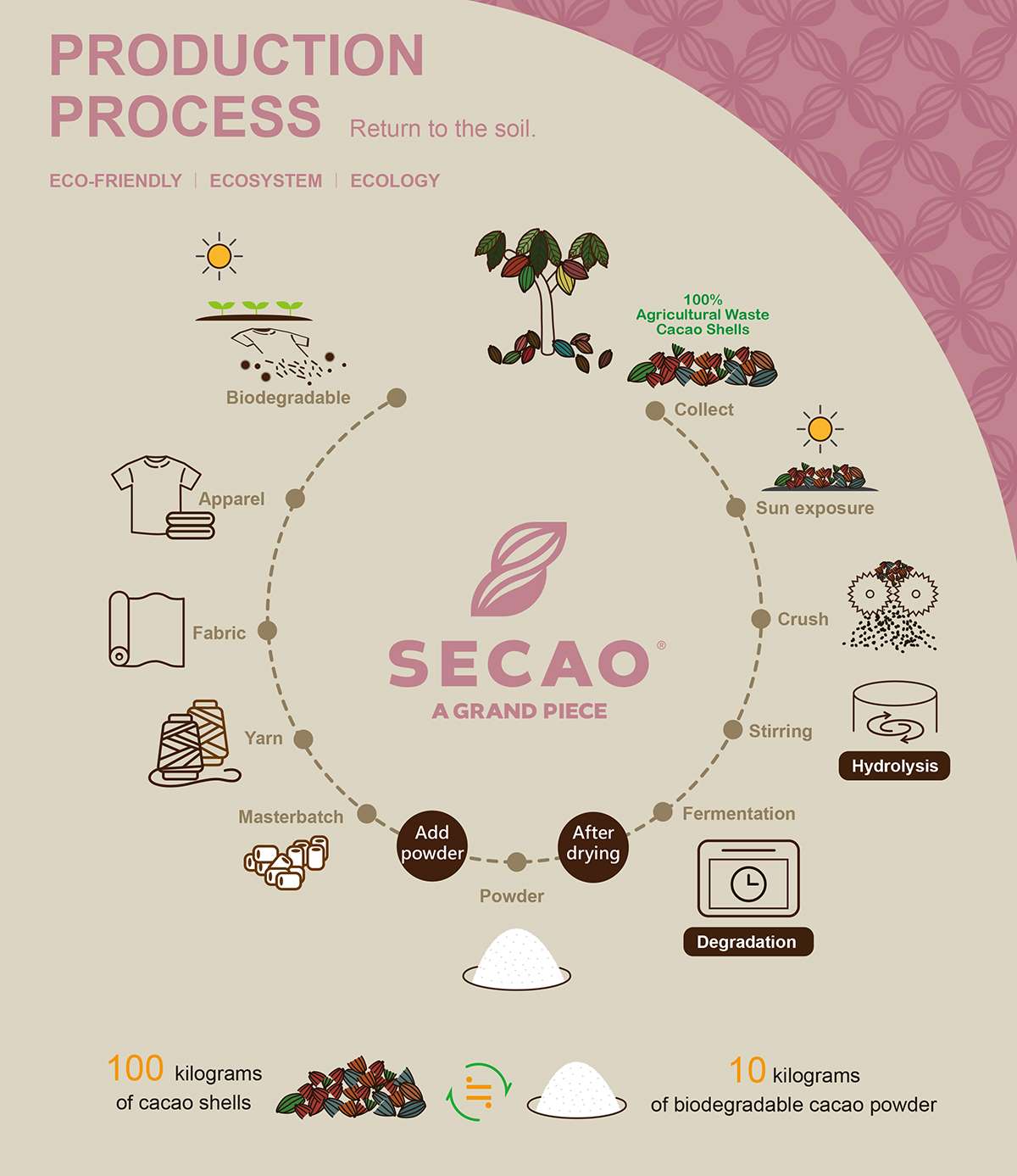

Every year Southern Taiwan produces 2,000 tons of cacao but only 20% of the fruit is processed for chocolate. The pulp and the seeds are used while the remaining husk – which constitutes 80% of the fruit – is considered agricultural waste and destined for incineration. But GrandeTex has developed a process that is giving the husk a new form of life by processing it into a biodegradable yarn, known as Secao®.

GrandeTex sources 100% of its cacao shells from local organic agricultural industries in Taiwan. The farmers collect the husks and leave them to dry out by sun exposure before they are crushed in preparation for GrandeTex’s production process. This involves mixing the crushed husk with an enzyme – made according to an exclusive formula – and then leaving the mixture to ferment. This produces a carbohydrate that can be added into the Masterbatch process to make a biodegradable yarn similar to polyester and nylon that can be spun into a fabric.

“It’s not just used for fabrics either – we are making garments for people as well now and they are really comfortable,” says Hsieh. “Because the fabric is made from nature is has a more natural feel. It can also be dyed like other fabrics and has great moisture management.”

Now Grandetex’s R&D team is looking at using a similar process to that developed for Secao® to process agricultural waste from local farmers who grow tea and passion fruit plants and create a biodegradable yarn that can be blended with other fabrics.

“We’ve been working with the local ATRI (agricultural technology research Institute) very closely on the innovation”, says Hsieh. “We’re developing more ECO products that we’ll be presenting to market early next year. We’re honoured to be making products that help the planet, these are exciting times for us to continue launching sustainable materials from Grandetex.”

Have your say. Join the conversation and follow us on LinkedIn