Sponsored by Yuang Hsian Metal Industrial Corporation

Ad. by TITA

Yuang Hsian Metal Industrial Corporation talks to WTiN about the journey of its AB65 copper alloy yarn: originally developed for sustainable fishing nets then adapted to make antistatic and antimicrobial medical and military textiles.

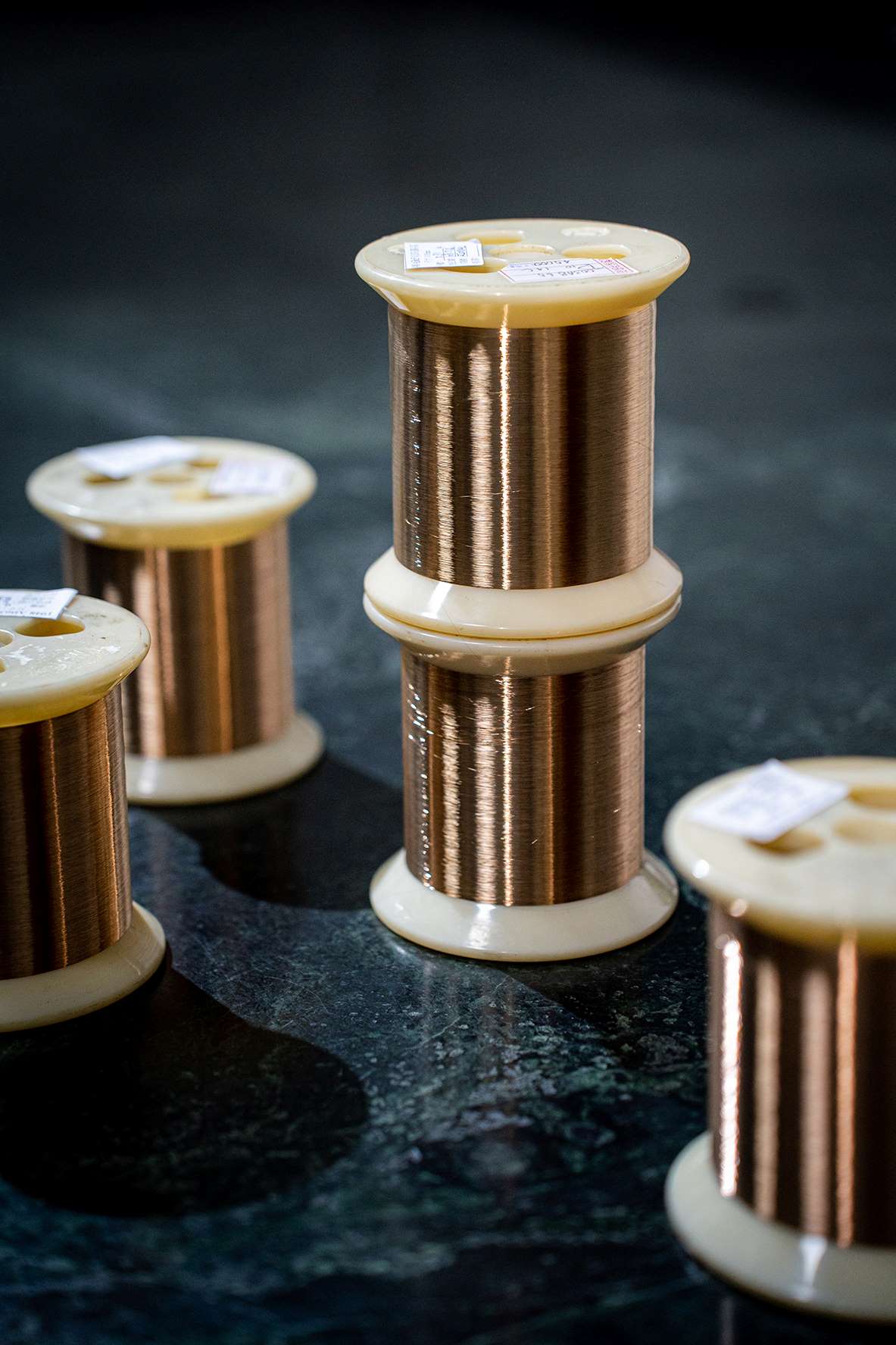

First founded as a copper alloy manufacturer in 1976, Taiwan’s Yuang Hsian’s Metal Industrial Corp has recently turned its expertise towards making antibacterial and anti-static copper alloy functional yarn for smart textiles. AB65 Copper Alloy can be used to make a wide range of apparel including socks, gloves, underwear, protective gear, woven and knit fabrics, and more.

In addition to having antibacterial and antistatic properties, the yarn is also said to be mildew-proof, conductive, far-infrared, and can withstand launderability.

As a smart textile, its electronic transfer functionality offers possibilities in the military sector, according to Yuang Hsian’s project manager Bond Chang.

“AB65 yarn, made from a copper alloy, boasts excellent conductivity properties,” Chang told WTiN. “For antistatic applications, the resistance of electricity is typically about 10^9 to 10^12 ohms. For conductive effects, the resistance ranges from 10^3 to 10^5 ohms and, for shielding purposes, it ranges from 1 to 10^3 ohms.”

With an electricity resistance of approximately 350 ohms per meter, the yarn is also designed to be anti-corrosive and appropriate for antistatic and shielding functions.

The product is suitable for medical-grade antibacterial requirements, having recently undergone Taiwan functional textile medical-grade testing, building on its prior certification by the Japan Textile Association with the SEK Red and Orange mark.

“After passing Japan’s SEK antibacterial test, we sought further challenges and achieved medical-grade certification after 100 washes,” says Chang. “Typically, chemical processes are not very durable with washing, but our unique feature lies in using pure metal fibre material without chemical agents or coatings.”

The product has passed oral toxicity and skin sensitivity tests, with antibacterial efficacy against the bacterium Staphylococcus aureus and Pseudomonas aeruginosa, achieving a 99.9% antibacterial rate after 100 washes.

“While these functionalities are common in the textile industry, our materials are entirely metal-based without coatings or chemical dipping, providing peace of mind for manufacturers,” says Chang.

“Initially, comfort was a challenge, but after years of research and development, we achieved a level of comfort suitable for human contact without allergic reactions,” says Chang.

Starting with sustainable marine aquaculture

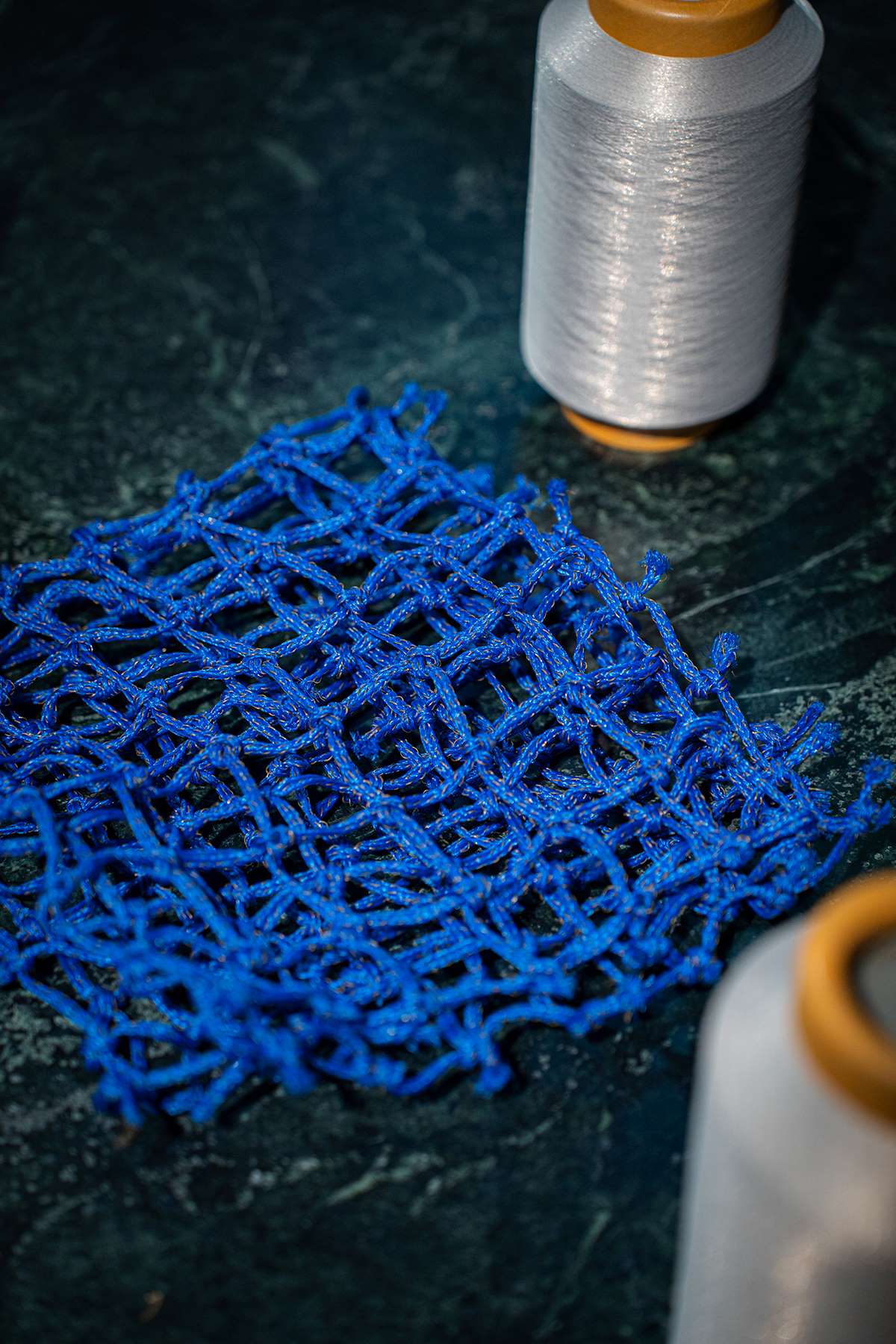

The journey towards launching AB65 began in 2013 when the International Copper Association asked Yuang Hsian to develop a sustainable alloy material for use in marine aquaculture nets in conjunction with its ocean cage aquaculture project.

“The goal was to replace the abundant ocean plastic waste – specifically, discarded plastic fishing nets – and promote healthier living conditions for the organisms being farmed,” explains Chang.

Through continuous testing and refinement, Yuang Hsian’s R&D team developed AB65 yarn: a material that consists of six elements, including five metals and one non-metallic element.

The yarn’s sustainable credentials come from the fact that it doesn’t rely on chemicals or coated fibres, which means it doesn’t have peeling issues and therefore doesn’t release chemicals or microplastics into the environment. This can also reduce the need for medication and manual labour during the aquaculture process.

“To demonstrate its safety and effectiveness, we utilised AB65 alloy to create fishing nets for aquaculture. Compared with plastic nets, fish raised in AB65 nets showed better health and increased growth rates, greatly satisfying fishermen.”

Expanding beyond marine applications, Yuang Hsian downscaled AB65 for use in inland fishponds to rear young fish and shrimp.

“This application resulted in higher survival rates and accelerated growth among the aquatic population,” says Chang.

Fishing nets made with AB65 are also designed to be easier to recycle. Chang says the yarn can be recycled using purely physical methods, unlike plastic polymers, which require chemical treatments for breakdown and recycling.

“Typical plastic fishing nets require thorough cleaning before recycling to remove contaminants, followed by shredding and the addition of chemical substances to break chemical bonds,” explains Chang.

“This process may involve significant chemical usage. In contrast, our fishing nets made from copper alloys can be easily recycled by melting them down in a furnace, similar to adding sugar to coffee. This process is simple and does not require extensive chemical additives, making it more environmentally friendly.”

Broadening the application to textiles

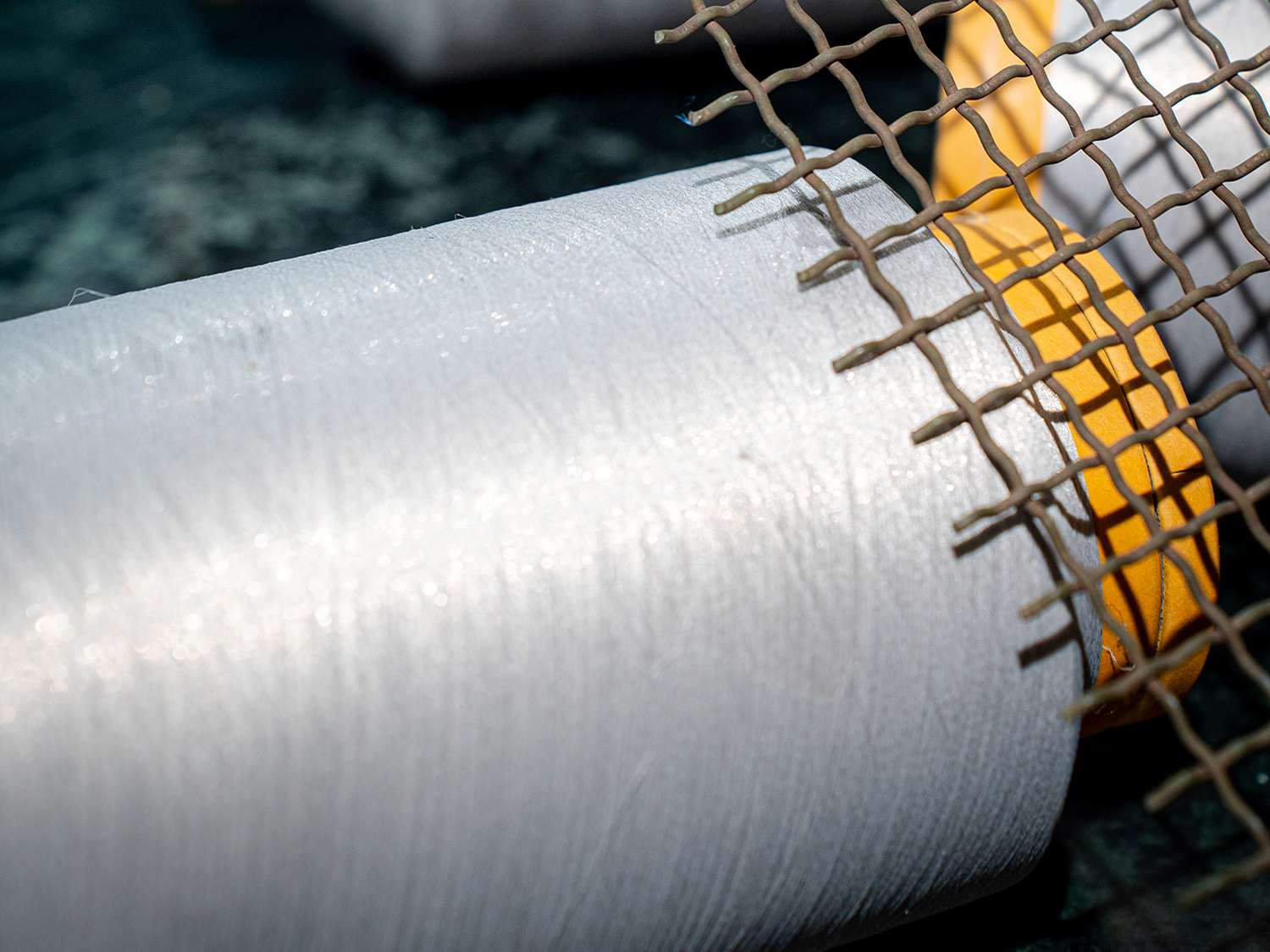

Building on the success of AB65’s application in the fishing industry, Yuang Hsian’s research team began work on ways to reduce the size of AB65 down to a diameter of 30mm for wider textile applications.

From initially being compatible with only a few textile machines, AB65 can now be used with most textile machinery, according to Chang.

“Our materials can be utilised in weaving machines, knitting machines, and even sewing machines. They can be incorporated into fabrics, clothing, underwear, socks, gloves, and various textile end products,” says Chang.

He believes the conductive nature of Yuang Hsian’s materials makes them suitable for a broad range of smart textile applications and they offer enhanced functionality in wearable products. For example, the company has used its yarn to manufacture socks with antibacterial properties for diabetic patients.

“Some diabetic patients have reported improvements in their condition after wearing these socks, and they help prevent bacterial infections that can lead to ulcers,” says Chang.

And this is not the end of the story. Yuang Hsian is continuing its advances in research, development and manufacturing and is seeking new partners to collaborate on developing further smart textiles that offer benefits to the environment and human health.

“Taiwan has long been a partner for many brands, continuously developing new products based on market demands, delivering the best under brand concepts, thus serving as a robust bridge between brands and consumers,” says Chang.

Yuang Hsian’s ISO-certified factory is designed to guarantee data management throughout material intake and production processes and every stage of production is meticulously documented and digitised for full transparency.

Chang believes the company’s avoidance of using petrochemical raw materials in its production process makes it a greener alternative to traditional textile processing.

“We can also provide small quantities of yarns to collaborate with manufacturers on researching and developing new textile products,” says Chang.

“We do not enforce strict minimum order quantities, aiming to collaborate with manufacturers in research and development and embrace the dawn of textile industry recovery together.”

Taiwan Functional Textiles will be showcasing fabric made from Yuang Hsian’s medically certified AB65 yarn at its booths at the NW Materials Show in Portland, Oregon, US from 28–29 August and Performance Days in Munich, Germany from 23–24 October. Interested visitors can leave their contact information at the booth or email info@ab65ft.com for further details.

Find out more about AB65 on YouTube and at www.ab65ft.com.

Have your say. Tweet and follow us @WTiNcomment