-

Understanding the commercial readiness scale

WTiN’s Commercial Readiness Scale gives an indication of what stage of commercialisation a product is at. It ranges from Emerging: a research stage development; Scaling: the product is being produced on a small but growing scale, and Commercialised: the product is well-established and ready to purchase.

Otis Robinson speaks with Lilach Porges, founder of Procode_Dress, about its use of a new 3D printing process at its New York Fashion Week debut and an associated patent-pending development.

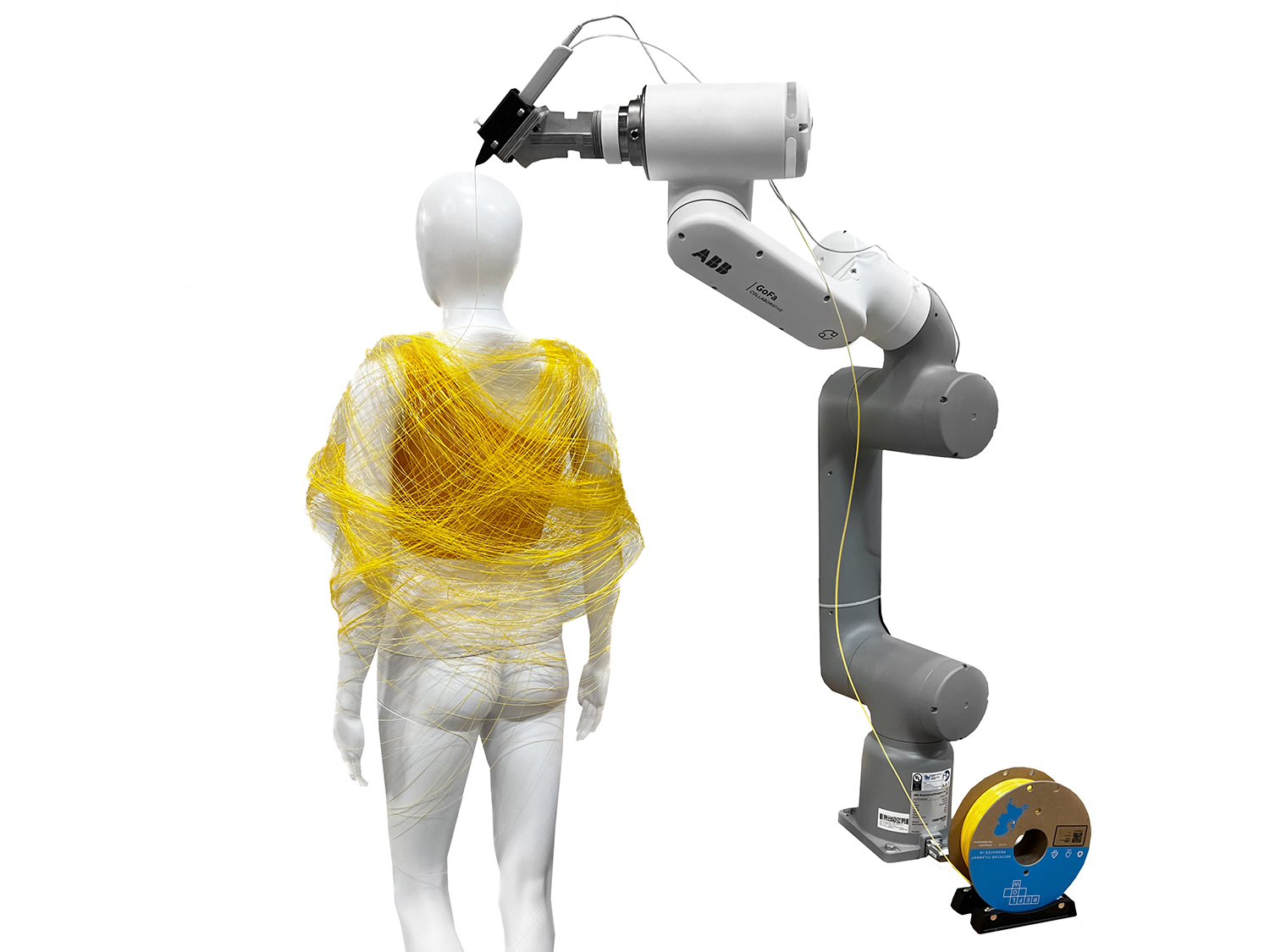

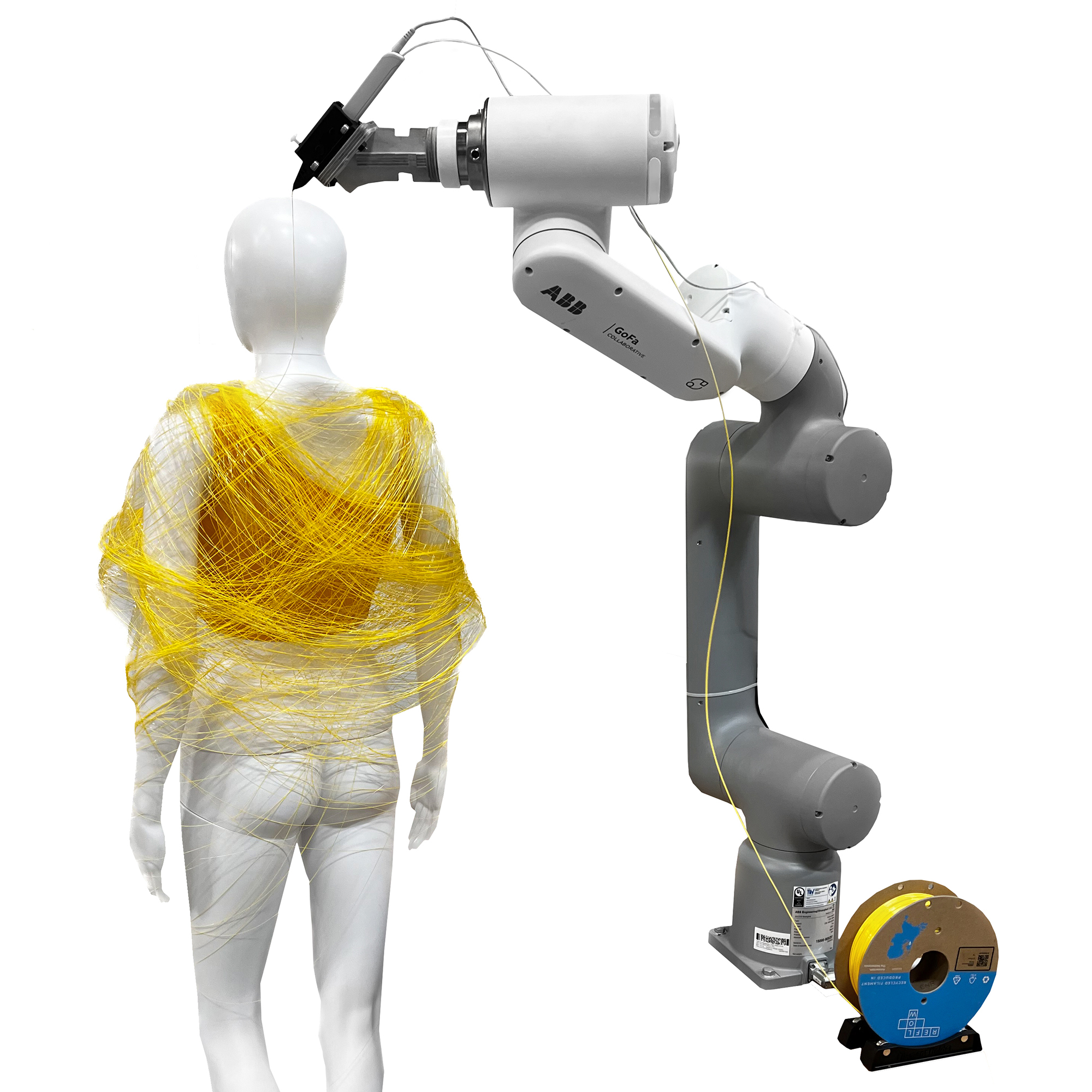

In February 2024, buzz circled emerging fashion brand Procode_Dress following its showcase at Tals Studio at New York Fashion Week (NYFW) in the US. For its Roller Coaster collection – constructed using a 3D-printing robot arm – founder Lilach Porges sought to innovate fashion manufacturing concepts.

Using 3D-printing technology and robotic arm technology from organisation New Bedford Research & Robotics (NBRR) and automation solutions provider ABB, Porges draped 3D-printed material over a rotating mannequin. With an apparel base – for example, a bodysuit, dress or top made from stretchy pre-sewn material – the 3D-printing process can commence atop the garment.

The result: the Roller Coaster collection, which featured a netting of threads across the body.

Doubly appealing to audiences was its use of sustainable materials. The process utilised recycled carbon fibres and bio-based ethylene vinyl acetate (EVA) derived from raw sugar cane from sustainable 3D printing materials provider Xtellar. It also used recycled plastic waste from peer Reflow.

Where many 3D-printed fashions have been “solid and heavy”, Porges notes that her garments – which she says can be recycled at their end-of-life – are lightweight, bendable and drapable.

Considered a “dynamic exploration of sustainable materials” and “visionary show” from network peers, Porges’ Procode_Dress represents the myriad new application possibilities of 3D printing technologies in fashion and an intention to make its unique effects on garments marketable.

The showcasing at NYFW acted as Procode_Dress’ – and Porges’ – debut. “I’m so excited to have my first fashion presentation as Procode_Dress in NYFW,” Porges wrote on Instagram prior to the show. “I will showcase a new ready-to-wear robot-printed fashion – the Roller Coaster collection.”

Patent pending technology

A former student of architecture at bachelor’s and master’s level, Porges later studied at the Fashion Institute of Technology (FIT) in New York. Porges’ thesis involved the development of three methods to 3D-print with robotic arms.

“One of the methods is currently patent pending,” she explains. This patent-pending method, titled Accurate Print – focused on printing accurately to body shape – posits that a whole dress, including sewing, zips, buttons and more could be created by the robotic system. “The idea, really, is that the robot will print all of the garment in one piece, and when it’s done, the garment [will be] ready for sale.”

Currently, Porges claims to have a prototype of Accurate Print at the ready – albeit “still in development” – but is awaiting patent approval before moving forward with further development or scaling. Although Porges is unable to share with WTiN any further details or footage of the system in action, she claims her “future factory” technology, which would implement recycling machinery too, is a game-changer.

According to Porges, tests show the system could print a garment in 12 hours or less. When pressed on whether this limits the process to luxury, small-run orders, Porges says, “Yes, and no”.

Porges explains her vision: “At the beginning, it could be more luxury, [especially] because it takes time to build a factory [around it]. It takes time for a technology to develop and advance. But, growing slowly, it will get to a point where I have a factory full of robotic arms.

“And I don’t see it as just one big factory for my brand – I see it as something I can sell. Other brands – small and large – [could buy] the system. It can be made more complicated or [simpler], depending on the consumer and target market. The idea is to place them near big cities, solving supply chain problems and sustainability [issues].”

Porges concludes that her vision includes improving the social and environmental sustainability of the industry – specifically, bettering working conditions through advanced technologies, decreasing the use of unsustainable materials and cutting down supply chain lengths to consumers.

For more information, visit www.procode-dress.com.

Have your say. Tweet and follow us @WTiNcomment