Sponsored by Taiwan Textile Federation (TTF)

WTiN talks to Taiwanese yarn manufacturer Toung Loong about its sustainability focus, striving for perfection and its move towards automated production.

In today’s increasingly competitive marketplace, textile manufacturers need to continuously adapt to market trends to stay afloat. Not only this, but sustainability must also be a priority – with a particular commitment to carbon neutrality. Taiwan-based textile and yarn manufacturers have long been at forefront of high-quality production of functional textiles and yarns and are increasingly pivoting to more sustainable options.

Toung Loong is a Taiwanese yarn manufacturer that has positioned itself as an innovative, sustainable, and forward-thinking company dedicated to producing high-quality yarn while minimising its environmental impact and adapting to the changing needs of the global textile market.

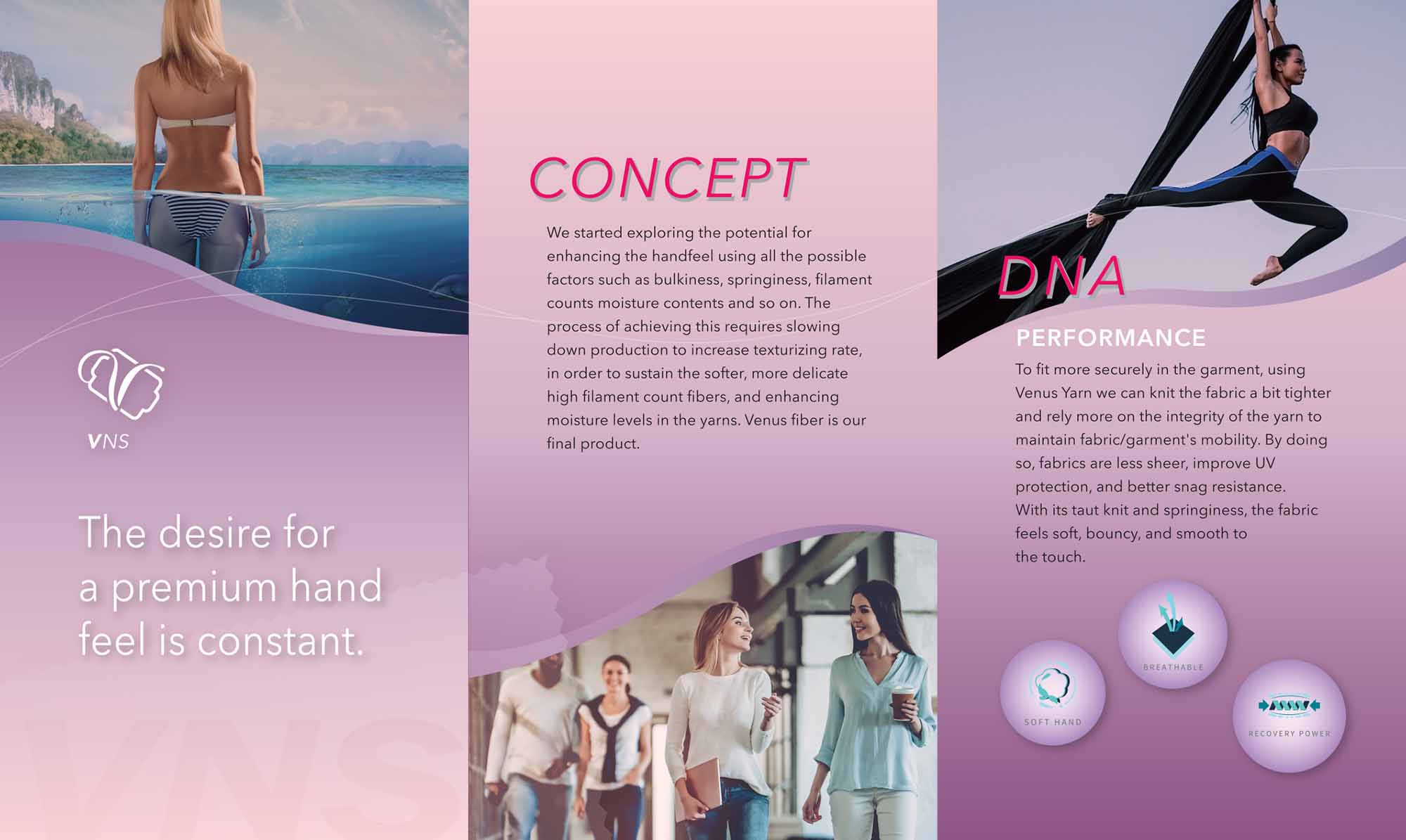

The company has a long history of innovation. For example, the continuous development of new yarn technologies such as its VNS yarn which is premium drawn textured yarn (DTY) and broadens options for DTY-like products such as sportswear (particularly sports bra’s and leggings). “Toung Loong DTY has been adopted by famous apparel brands and beloved by global users for its stretch, bulkiness, and a super soft hand feel.

Additionally, the company’s SCT (Shape Control Twist) process is a special yarn texturing process developed by Toung Loong that can maintain the cross-section shape of textured yarns, especially performing well on hollow cross-section fibres. The company explains: “During texturing process, it’s known that the shape of fibre is hard to maintain. However, the heat preservation (clo) value relates to the shape of hollow cross-section fibre directly. Toung Loong Textile MFG has developed this unique SCT process to maintain the shape of functional fibres during the yarn texturing process.”

These two developments are examples of how Toung Loong is constantly experimenting and striving for perfection, the company says. “As long as there is room for improvement, we will continue to develop to reach a level that others cannot achieve. The excellent hand feel of VNS and the cross-section retention of SCT are the results of our hard work and development.”

Low impact solutions

Looking to the next innovations in yarn development and process improvement, Toung Loong’s focus will be firmly on developing environmentally friendly solutions. For example, the company says: “Improving hand feel to replace fabric brushing, as brushing causes microfibres to shed, polluting the oceans and the entire ecological chain. At the same time, we will also focus on developing fabrics made from a monomaterial to achieve garment recycling, enabling the entire textile industry to recycle the products it manufactures.”

Toung Loong also plans to increase the proportion of recycled materials used in production. However, the company is aware that with the use of non-virgin materials, there can be challenges. It says: “As more manufacturers increase the use of recycled materials, there will inevitably come a day when supplies run low. The textile industry must establish an internal recycling loop within its own sector. Toung Loong has created the special Springfil yarn, which is 100% recyclable in finished garments while offering comfortable stretch.”

As well as materials, Toung Loong also seeks to streamline manufacturing processes to increase sustainability and manufacturing efficiency. For example, the company emphasises water recycling in its Colorfit dyeing process. The company said: “Toung Loong strives to minimise the energy required throughout the entire dyeing process.” To do this, its dyeing tanks are covered with insulating materials to reduce the steam needed for heating. After measurement, it was found that the insulation reduces steam usage by at least 12%.

The company continues: “Also, by increasing the yarn's weight during dyeing, the bath ratio is also reduced, significantly cutting down the water used during dyeing. At the same time, a large amount of recycled water is used, with the proportion of recycled water reaching 40%.”

In addition to increasing the proportion of recycled water used, the Toung Loong says it is continuously expanding its installation of solar panels. “Additionally, we pass OEKO-TEX and bluesign certifications every year to ensure that all products are non-toxic and environmentally friendly. In the long run, Toung Loong's ultimate goal is to achieve carbon neutrality, helping to avoid accelerating global warming.”

Business development

As the entire apparel industry evolves, Toung Loong continues to push to higher performance products with sustainability in mind. “Our continuous efforts in researching and developing innovative technologies and products are aimed at meeting the future diverse demands in the apparel industry,” the company says.

It is important to the company though, to not focus on mass production and instead dedicate itself to customised production at a smaller scale in a shift away from the commonplace narrative of fast fashion.

However, as well as significant opportunities in the market, Toung Long has positioned itself to address key challenges as well: “It’s not just the textile industry but we believe that the biggest challenge the entire manufacturing industry will face in the future will be labour-related issues. In today’s society, as we move towards a declining birthrate, it will become increasingly difficult to obtain manual labour, so we must shift towards automated production”.

The company concludes: “Toung Loong has already begun to make plans and is gradually introducing automated equipment while also integrating artificial intelligence (AI) to optimise the entire production line.”

Have your say. Tweet and follow us @WTiNcomment